Fifteen years back Ibomcha use to read Taiwan catalogue and magazine on Bamboo. One time president of All Manipur Entrepreneur Association Rishikumar gifted him the catalogue which was enriching. He kept on thinking of making Bamboo furniture but could not materialize. He recollected all his efforts and finally ventured into making Bamboo furniture.

By James Khangenbam, Imphal 28/06/2023

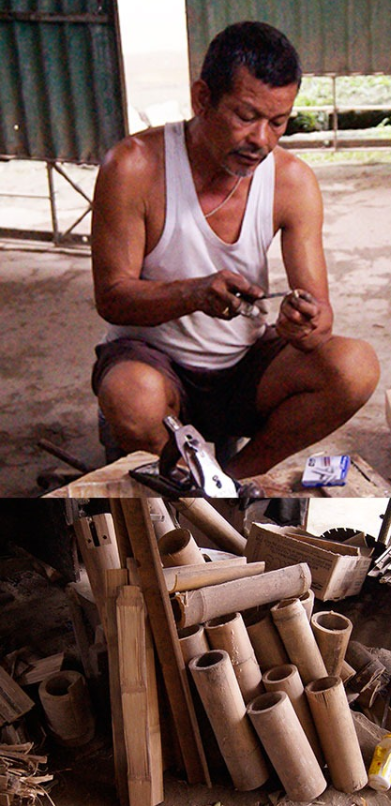

His bamboo products are seamless. In a chair he uses eight nuts in the bottom area and 4 nuts in the upper part. It could be exported in any part of the world as it is built for easy transportation and could be assembled with the nuts when the furniture reaches the destined place of export. In the round table furniture he uses three nuts down and three nuts at the upper part. The furniture are quite strong and many have bought from him since the last many years.

Bamboo furniture

Chair, Table, Portable Mirror Stand, Tray, Mementoes, in a seamless set up. All of them are folding and could be dismantled. A Round table and three chair set took one week to complete.

He is working on his latest design a chess board with colour pattern originally from the Bamboo texture arranged in 64 squares with an eight by eight grid.

He is searching for craftsman who can Bamboo design the 16 pieces: one king, one queen, two rooks, two knights, two bishops, and eight pawns

Why Bamboo furniture

According to Khwairakpam Ibocha bamboo surface has shining property unlike woods. He is trying to make furniture like doors and window. He has successfully fixed two bamboo surfaces together to thicken the board as doors needs to be thick. If his work shed is more mechanized it will be more productive. It is half manual and half machine as of now.

In Countries like Thailand and China Bamboo work sheds are mechanize so they have same size and uniform products. Cost of a Bamboo Board imported from China and marketed in Kolkata cost Rs250 per square feet.

He is making bamboo hard boards with 2 inch: 2 inch thick bamboo boards joined together surface to surface. Thus a 4 inches thick bamboo board is ready to materialize in a grand and strong furniture.

He uses a Fevicol company glue Pur ‘to join the surfaces together. Pur saves time. Earlier a normal Fevicol glue took five hours to stick two bamboo pieces together. In 20 degree Celsius temperature it stick in 60 min, 40 degree Celsius took half an hour. If fixed in 60 degree Celsius temp it can be done in 10 minutes.

Now I can stick two surfaces in 45 minutes with the new gum of Fevicol Company says Ibomcha who was working in his work shed when Manipur Times interacted him.

Bamboo treatment

Bamboo are harvested in mera’ season and dip in water for a month and dried in sun. This is indigenous method and time consuming.

Chemical treatment is modern as found in various newsletter. He uses boric acid and borex in the ratio of one times of boric acid and one and half borex. In 200 litres of water 500 ml Boric acid is added and 750 mg of Borex in 200 liters of water. After the two samples are mixed He dips the bamboo for three hours.

He innovated a method by making water mixture in a mobil drum and he uses steam bath method by boiling the mixture and treating with the steam. This is how he treats his Bamboo. It proves good as it takes away the water content in steam bath. Thus the bamboo do not get shrink from the water content for a longer time.

So far Ibocha has officially trained 20 people under the sponsorship of Commerce and Industries Department Government of Manipur. The government sanctioned Rupees one lakh and ninety thousand for the training.